After several days spent in Harrachov — a small village in the Krkonoše mountains, I was happy to visit one of the most attractive museums in the region: Harrachov Glass Factory.

This is the place where magic happens: quartz sand after several manipulations is turned into gorgeous pieces of Bohemia Crystal glass. As usually I did my best not only to see the whole process by myself, but also to capture some photos and to make a video about how Glass Factory in Harrachov works.

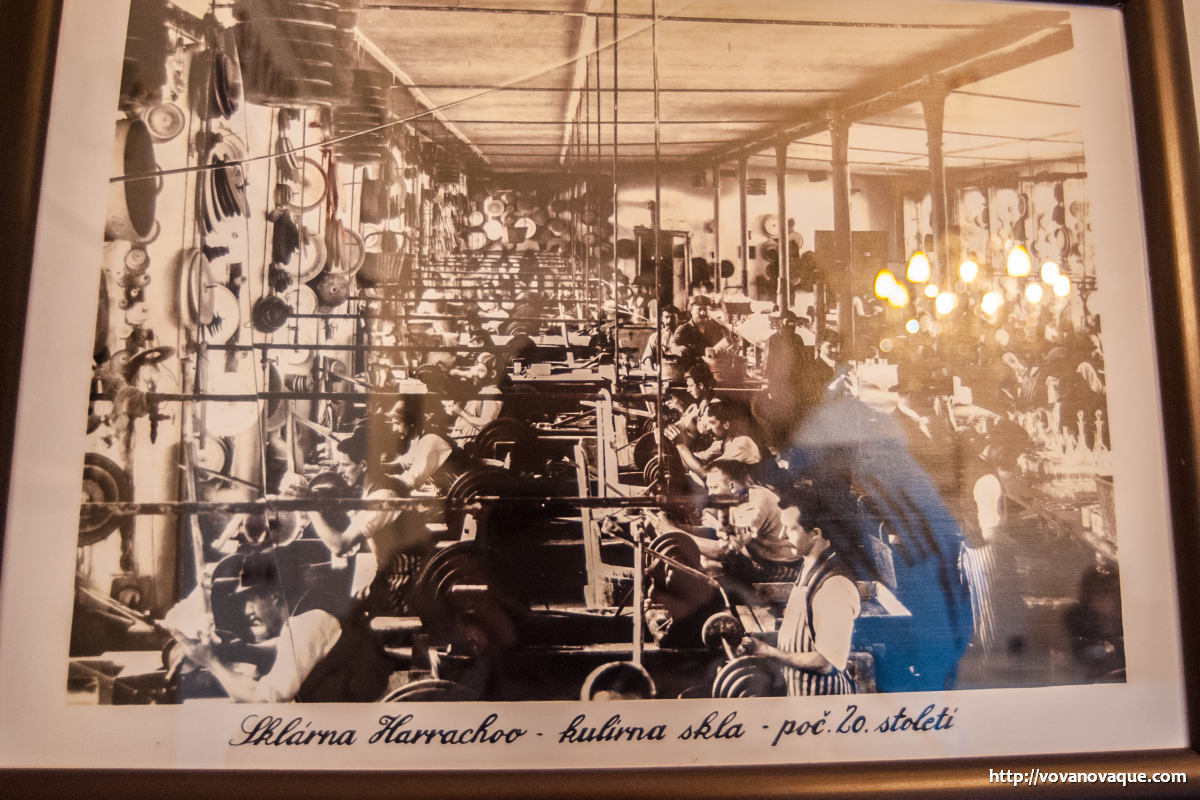

History: it began 300 years ago

In 2012 the crew of the factory was celebrating 300 anniversary of the manufacture. It means that the first officially made glass left the walls of the workshop in 1712. Since that times almost the whole procedure in Harrachov Glass Factory remained the same.

There was no need to change anything, because strong demand on the products made of Czech glass worldwide was growing every year.

There were a lot of ups and downs in the history of the Harrachov Glass Factory. The wars, changes of governments and regimes, internal and external factors were influencing it. But the last and most hard impact was made by the growing number of Asian glass producers. They learnt how to make the Bohemia Crystal Glass fast and cheap. As a result they took a huge piece of the global market.

Local manufactures likeHarrachov Glass Factory started to work only for individual requests. More and more people start to value how precious manual work is. Now, the manufacture produces goods under the famous brand Bohemia Crystal Glass.

Manufacturing in Harrachov Glass Factory

The procedure of the making glass from sand is pretty simple. It has been known since 3500 BC in Mesopotamia. But every region in different historic periods had it is own peculiarities of production. Harrachov Glass Factory is unique in its engine. Moreover it is one of the places on the Earth where only old traditions and methods of production are still used.

Before going closer to the furnace, the workers have to make special wooden forms. These forms are used to shape the soft glass. Such blocks have special locks and handles to manipulate them.

When the tools are ready, the teams of glass-makers start to work. Taking hot red soft glass piece by piece from the furnace they begin the magic process. It is divided into several steps. In the team every worker is responsible for certain operation with glass.

When you look at glass-makers from the top it seems that they are like robots. They repeating one and the same move. The only difference is the beer — robots don’t need it to work. As the guide told us, the beverage is reach on vitamins and minerals. Therefore in Harrachov Glass Factory the workers drink at the working place.

When the glass is shaped, the next person gives it a footplate. After the whole piece travels through a special cooling line for 2 hours.

Polishing

After the glass cools down they start to polish it and to give a pattern. The cup of the glass is cut with a special tool, which leaves quite sharp sides dangerous for lips. Therefore, the other step is manual work made by experienced people who can notice and fix all the sharp parts.

But even after the polish, a glass travels to washing machine. In few words this is how they make Bohemia Crystal Glass in Harrachov Glass Factory.

The last step is the quality control, where every piece is examined carefully for bubbles or any other possible faults. According to the number of certain defects they divide products in various classes. The broken pieces are thrown into the yard where visitors can practice in throwing the glass into the wall. Have a look at the video below. I tried to show how hard it is to produce and how easy it is to brake a glass.

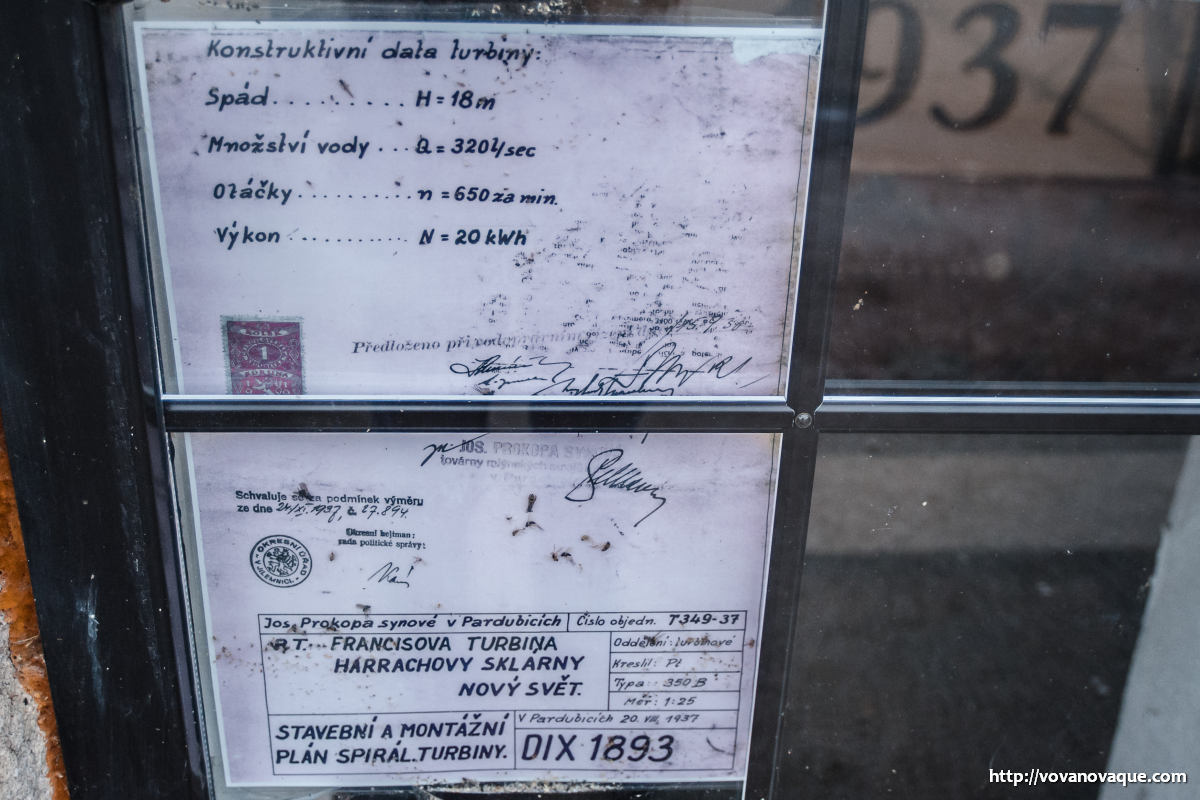

Unique water turbine

The place where they built Harrachov Glass Factory was chosen according to the geographical location and access to resources used during the production. One of the most important things was wood, which served as fuel to melt sand into glass. The second one was water — which made the turbine go. If the former was changed with more productive fuels, the latter remained.

Today Harrachov Bohemia Crystal Glass factory is proud to be using the oldest functioning water turban in the world, the capacity of which is 20 kWh of energy per day. Water falling down through a pipe from the mountain rotates the turbine which makes the belts move.

Museum and store

The museum of glass in Harrachov Glass Factory shows a huge collection of works produced in the manufacture during the whole its history. Now, I truly understand Americans and Canadians who have always been ordering a lot of glass products from Harrachov.

It is amazing! But it is a petty that they don’t allow to take photos and film video in the museum, which is quite stupid, because nice pictures may attract more and more clients and promote the works. But a man is the king in his house.

Brewery

There is also a brewery at the territory of Harrachov Glass Factory, where one can try local beer and traditional Czech food. Buying a ticket to see the manufacture, you get also a free beer or a soft drink in the brewery upstairs.

Of course me and my friends used the chance to have a free drink. Can’t say anything about the food, but the couple sitting at the same huge table, where we were having our drinks, gave the waiter absolutely full plates back, which prevented us from ordering anything there. This is just a friendly note to my friends and fellow travelers, willing to see Harrachov Glass Factory.

Genearl information

- Officail page: sklarnaharrachov.cz

- Open: 9:00 – 17:00

- Address: Nový Svět 95, 512 46 Harrachov, Czech Republic

- Tickets: 120 Kc (≈5 Euros) including a drink and a discount for the shop